There are four bouge's Compounds.

1. Tri Calcium Silicate (Aelite) C3S:-

Formula = 3CaO.SiO2

Percentage = 40%

Functions:-

2. Di Calcium Silicate (Belite) C2S:-

Formula = 2CaO.SiO2

Percentage = 32%

Functions:-

- It provides hardness and strength in final/later days.

- Less heat of hydration.

- Due to less heat of hydration , in initial days sulphate acid attack is less.

- More heat of hydration in later/final days (240 KJ/Kg).

Formula = 3CaO.Al2O3

Percentage = 10%

Function:-

- It provides quick hardening.

- Heat of hydration (864 KJ/Kg).

- Flash-set.

- It provides initial setting.

Formula = 4CaOAl2O3Fe2O3

Percentage = 8%

Function:-

- It provides quick setting.

- Heat of hydration (420KJ/Kg).

A B C Fraud आदम है l

A- Aelite

B- Belite

C- Celite

F- Felite

Flash-Set:-

- Flash set is the stiffening of cement paste without strength development with heat evolution. It is caused by (C3A).

- Tri Calcium Aluminate reacts immediately with water & is responsible for flash set.

Water Requirement for hydration:-

Hydration of cement is exothermic process.

Bound Water = 23%

Gel Water = 15%

Total Minimum = 38%

Rate of Heat evolution ➝C3A>C3S>C4AF>C2S

Rate of Hydration →C4AF>C3A>C3S>C2S

Special Points:-

- It is found that OPC achieves 70% of its final strength in 28 days and about 90% in one year.

- Gypsum is added to cement to reduce flash setting.

- Gypsum is usually mixed with clinker before final grinding.

- Gypsum retards setting time of cement.

- Excess of gypsum makes cement unsound.

- So gypsum added to clinker should not be greater than (2.5-3%).

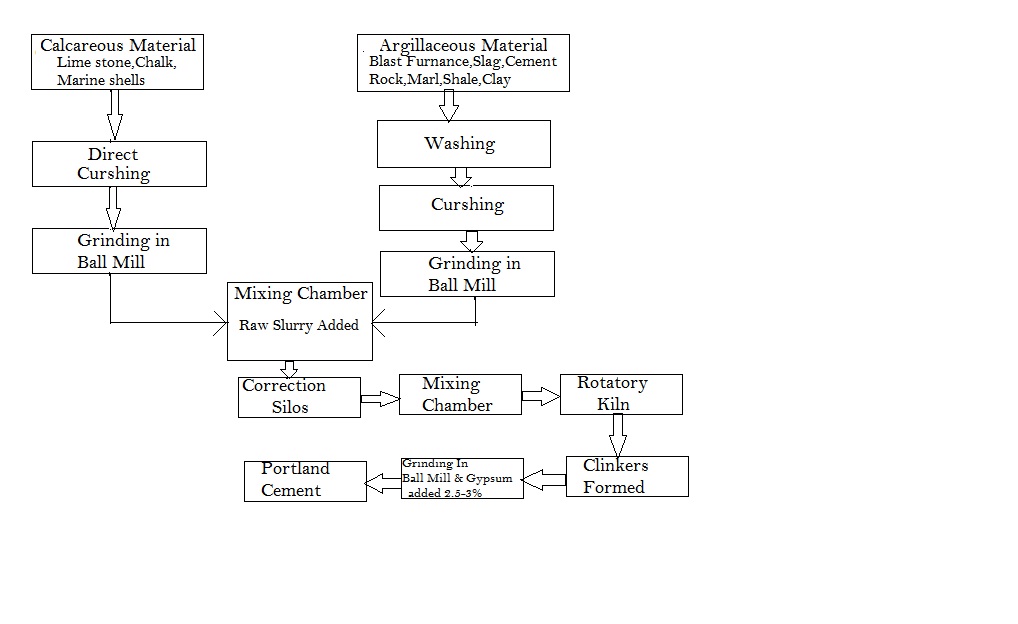

There are two process of manufacturing of cement.

- Dry Process

- Wet Process

- In the dry process the calcareous and argillaceous materials are crushed and grinding separately and after grinding mixed in the mixing chamber with 4% amount of water.

- After mixing the calcareous and argillaceous materials the mixed proportin comes in the correction silos.

- In correction silos some materials added in the mixed powdered form of cement.

- And again in mixing chamber.

- After the mixing process the powdered form of cement comes in rotatory kiln for heating purpose at a temp. 1400°C.

- After the heating process the material comes in the correction silos.

- In correction silos some materials are added and clinkers are formed.

- Clinkers are the small pieces of mixed material.

- Again clinkers are grinding and 2.5-3% of gypsum is added.

- And the Portland cement is obtained by the dry process.

- Packing and transporting is done of cement.

- In the wet process the calcareous materials are directly crushed and the argillaceous materials are first washed and then crushed.

- After crushing the materials the grinding is done in Ball Mill / Tube Mill.

- Both grinded materials are mixed in the mixing chamber and raw slurry is added.

- After that all the processes are same as the dry process.

- And Portland cement is obtained by wet process.

Nice blog, Thank you for sharing this informative blog with us. bonded ferrite

ReplyDeletePost a Comment